Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore. Since limestone is the main ...

Alternative Fuels in Cement Manufacturing | IntechOpen

In 1995 the world production of cement was about 1420 million tonnes (Cembureau, 1997). Cement production is an energyintensive process consuming thermal energy of the order of GJ/tonne of clinker produced, which accounts for 30 – 40 percent of production costs (Giddings et al., 2000; EC, 2001). Worldwide, coal is the predominant fuel ...

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships. Cement Manufacturing Process Flow Chart. After explaining the complete process of cement making, flow chart would be like that. flow chart present the summary of whole process as shown below.

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Cement Ufacturing Process Flow Diagram Pdf Portland Chart ...

Cement Ufacturing Process Flow Diagram Pdf Portland Chart Of Cement Manufacturing Process Flow Chart Flowcharts cement manufacturing process flow chart pdf cement ...

Integrated Pollution Prevention and Control (IPPC ...

Executive summary ii Cement and Lime Manufacturing Industries At present, about 78% of Europe's cement production is from dry process kilns, a further 16% of production is accounted for by semidry and semiwet process kilns, with the remainder of

): Automation solutions for the Cement Industry.

Growing pressure on the production side, ever shorter product life cycles, rising production demands and an ever greater complexity: The demands made on you as a system integrator are immense. The demand is for solutions with which you can process your customers orders more quickly, precisely and economically – from the design to commissioning.

DETAILED ENERGY AUDIT AND CONSERVATION IN A .

wet process in three separate cement plants, and now these have been wholly converted to dry cement process and modern technology. The management of this cement plant accords high importance to social responsibility and environmental ... PROCESS DESCRIPTION The production of cement involves two major processes, a.

Production Cement industry news from Global Cement

Jan 28, 2020· Figure 1: Russian Federal Districts by cement production in 2016. Source: Anecdotally, this change in the fortunes of the Russian cement industry can be seen in the volume of news coverage on the Global Cement website over the last few years. The mean number of news stories on the country in 2016 and 2017, increased by half in ...

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT ...

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY: A CASE STUDY FOR ZIMBABWE D. Zimwara1, L. Mugwagwa1, ... Cement Production Plant (Cement Company, Zimbabwe) ... the wet process, or the semidry process. If the dry process is used, the raw materials are dried using impact dryers, drum ...

National Emission Guideline for Cement Kilns

The National Emission Guideline for Cement Kilns was developed to provide a consistent national basis for restricting emissions of nitrogen oxides (N0x) ... Clinker production can take place in a wetprocess long kiln with a slurry raw material feed, with a dryprocess feed in a long kiln, or with a dry feed in more modern and efficient ...

Use of Alternative Fuels in Cement Manufacture: Analysis ...

Cement manufacturing is an energyintensive process due to the high temperatures required in the kilns for clinkerization. In 2005, the global cement industry consumed about 9 exajoules (EJ) of fuels and electricity for cement production (IEA 2007). Worldwide, coal is the predominant fuel burned in cement .

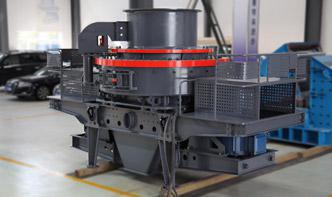

cement manufacturing process ppt | Mobile Crushers all ...

Cement Manufacturing Process Ppt Slides Free Downloads Machine. Jan 9, 2014 cement manufacturing process ppt download Gold Ore Crusher Cement Manufacturing . cement manufacturing process ppt . cement manufacturing process ppt from . Shanghai (cement manufacturing process ppt) is professional manufacturer, the main production stone ...

Cements – Composition, Types

Summary of the Cement Making Process. Some practical issues about cement making Scale of the business (local / national) LOCATION Plant operations Wet versus Dry process ... Microsoft PowerPoint CE 553 L5 Cements compounds and type Author: ceeguest Created Date:

Carbon Dioxide Control Technologies for the Cement Industry

Carbon Dioxide Control Technologies for the Cement Industry 1. Introduction 2. The cement clinker burning process 3. Assessment of carbon dioxide control technologies Precombustion technologies Oxyfuel technology Postcombustion technologies 4. Preliminary research results (Oxyfuel technology) Impact on raw meal decarbonation

Présentation PowerPoint Lafarge

THE CEMENT MANUFACTURING PROCESS quarry raw grinding and burning grinding, storage, packing, dispatch HOW TO USE THIS PRESENTATION : > once the animation has finished, click anywhere on the screen to move on > click on « next » to see the next stage of the cement manufacturing process Click here to start THE CEMENT MANUFACTURING PROCESS 1.

Various Steps Involved In Concreting Process Daily Civil

Curing is the process in which the concrete keeps its moisture for a certain time period to complete the hydration process. Curing should be done properly to increase the strength of concrete. Required Curing days: Ordinary Sulphate Resistant Cement – 8 Days. Low Heat Cement – 14 Days.

Manufacturing process | Home : Lafarge Cement

All about Cement » Manufacturing process; Manufacturing process . From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. ... This produces clinker, the basic material required for the production of all cements. CO2 and cement .

Cement Manufacturing Process And Quality Control1 ...

2 Cement Manufacturing process and Quality control Methods. Topics: 3 Topics Cement definition Types of cement Various cements Cement plant Machinery Various process of cement manufacturing Cement raw materials and Fuel Quality Control Parameters Applications of Cement Types Quality control tips Question and Answer session

The manufacturing process CEMBUREAU

From crisp packets to concrete buildings: the European Cement Industry demonstrates how everyday waste fuels cement manufacturing CEMBUREAU's response to The Guardian's 'Concrete Week' Eurelectric and Energyintensive industries call for an ambitious and comprehensive EU Industrial Strategy to enable industry's contribution to the EU ...

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

3 CEMENT PRODUCTION PROCESS AND ENERGY USE INTRODUCTION Cement is an inorganic, nonmetallic substance with hydraulic binding properties, and is used as a bonding agent in building materials. It is a fine powder, usually gray in color, that consists of a mixture of the hydraulic cement minerals to which one or more forms of calcium sulfate have

6. Wet processing | Textile Technology

Textile wet processing Textile wet processing is the process that use in any finishing treatment. Where, this process is applied on textile in form of liquid with involves some for chemical action on the textile. Examples: bleaching, , dyeing and . .

Wet Mix Macadam Process |authorSTREAM

Wet Mix Macadam Plant Wet Mix Macadam WMM is a relatively newer concept used for laying the base course which is placed right before the hot mix asphalt during road construction. The binding materials used for the base in case of WMM are prepared in the plant .

Cement manufacturing components of a cement plant

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages.

What Is Cement? Manufacturing, Composition their ...

Sep 17, 2013· There are 2 chief aspects of the manufacturing process: First To produce a finely divided mixture of raw materials – chalk / limestone and clay / shale. Second. To heat this mixture to produce chemical composition. There 2 main process that can be used in manufacturing of Portland Cement that is. i) wet process ii) dry process; WET PROCESS